Hasen-home Stainless Steel Shower Drains Factory Balances Craft & Tech

In the highly competitive bathroom fixtures market, Stainless Steel Shower Drains Factory face the challenge of balancing quality craftsmanship with production efficiency. As consumer demand grows for both durable and aesthetically pleasing products, factories must choose how best to integrate automation and handcrafted techniques in their manufacturing processes.

Automation offers significant advantages in terms of production speed, consistency, and cost-effectiveness. Modern automated machinery can cut, weld, polish, and assemble stainless steel shower drains with precision and repeatability. This reduces human error, minimizes waste, and ensures a uniform finish that meets strict quality standards. Factories equipped with advanced automation lines can fulfill large orders quickly, meeting the needs of commercial projects and large-scale residential developments.

On the other hand, handcrafted processes provide a level of detail and customization that machines alone cannot replicate. Skilled artisans can perform fine polishing, intricate pattern cutting, and bespoke customization tailored to unique client requirements. Hand finishing also allows for careful quality control at every stage, catching subtle imperfections and ensuring each piece meets premium standards.

The best factories combine the strengths of both approaches, creating a hybrid manufacturing model. Typically, automated systems handle repetitive and high-precision tasks such as cutting and initial welding. Meanwhile, skilled workers complete hand-finishing steps such as surface polishing, edge smoothing, and final inspection. This synergy maintains high throughput without sacrificing product excellence.

The following table summarizes the main benefits and challenges of automation versus handcrafted techniques in stainless steel shower drain production:

| Aspect | Automated Manufacturing | Handcrafted Manufacturing |

|---|---|---|

| Production Speed | High – capable of large volume output | Slower – limited by artisan availability |

| Consistency & Precision | Excellent – minimal variation between units | High – but variation can occur due to manual work |

| Customization | Limited – designed mainly for standard designs | Extensive – tailored to unique designs |

| Labor Cost | Lower per unit due to mechanization | Higher due to skilled craftsmanship |

| Quality Control | Built-in sensors and automated checks | Human inspection and experience-based judgment |

| Waste & Material Use | Minimal waste with optimized cutting | Potentially more waste but can be more selective |

| Scalability | Highly scalable to meet large orders | Limited scalability |

While automation is indispensable for mass production, handcrafted finishing remains vital for luxury and bespoke shower drain lines. Consumer trends increasingly favor unique bathroom fixtures that combine modern durability with artisan aesthetics, pushing factories to innovate in their production strategies.

Sustainability is another factor impacting the balance between automated and handcrafted methods. Automated processes tend to optimize material usage and energy consumption, while skilled manual work often reduces rework and extends product life through superior finishing. Factories adopting a hybrid approach can harness these benefits to reduce their environmental footprint.

In conclusion, stainless steel shower drains factories that succeed in today's market are those that smartly integrate automation and craftsmanship. This balanced approach allows them to meet diverse customer needs—from fast delivery of standard products to exquisite custom designs—without compromising on quality or efficiency.

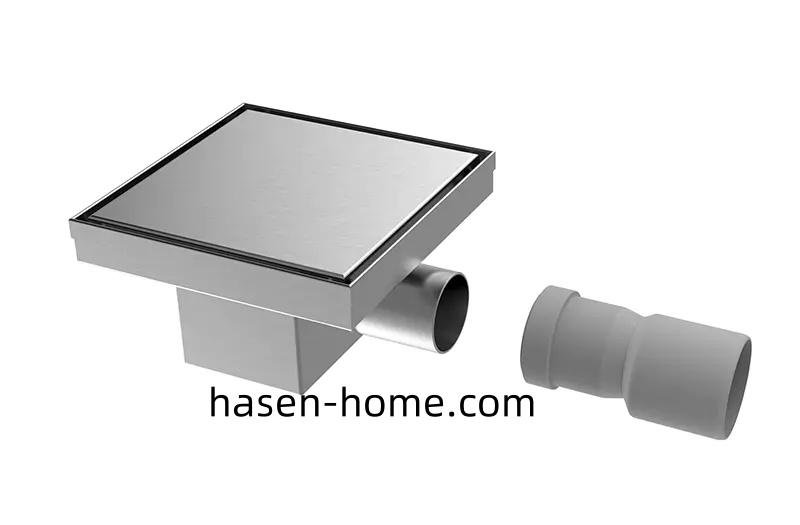

At Hasen-home, we embrace this philosophy by combining cutting-edge automated technology with expert craftsmanship in manufacturing stainless steel shower drains. Our factory ensures each product meets stringent quality standards and reflects the elegance demanded by modern bathroom designs. Whether for commercial projects or bespoke residential bathrooms, Hasen-home delivers reliable, durable, and stylish drainage solutions.

Explore our innovative stainless steel shower drain products and learn more about how Hasen-home leads in quality and efficiency:

https://www.hasen-home.com/news/linear-shower-drain-a-new-choice-for-innovating-bathroom-drainage-experience.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness