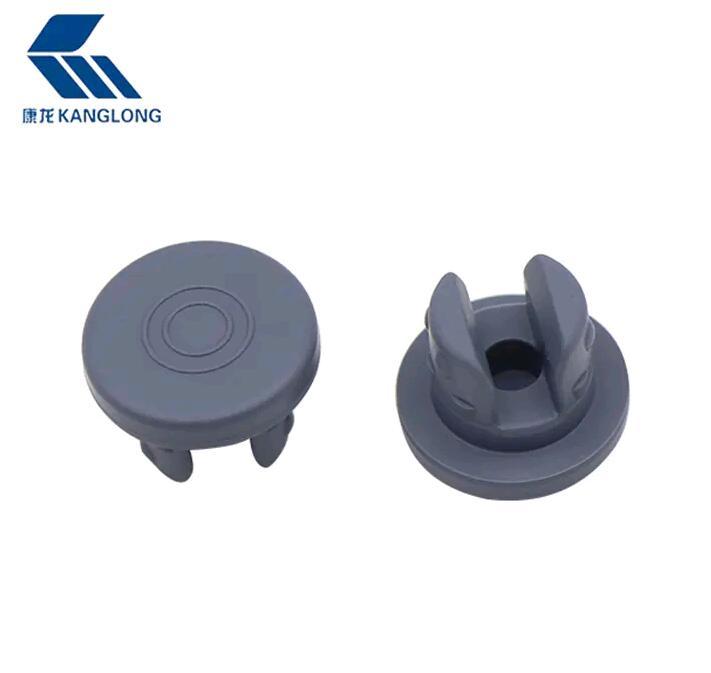

Medical Butyl Rubber Stoppers: Ensuring Purity and Sterility

Some freeze-dried stoppers incorporate silicone or fluoropolymer coatings to improve lubricity and reduce coring (the formation of rubber particles during needle penetration). These coatings help maintain the purity of the drug product and reduce risks during injection.

Additionally, the stoppers are designed to endure the low temperatures and pressure changes involved in the freeze-drying cycle without cracking or deforming. This mechanical resilience ensures vial integrity throughout production and storage.

Effective Moisture and Gas Barrier

Butyl rubber inherently provides a robust barrier against moisture and gases such as oxygen and carbon dioxide. This property is crucial for freeze-dried pharmaceuticals, which can be highly sensitive to moisture uptake and oxidative degradation.

Maintaining low moisture levels within the vial preserves the drug's stability and efficacy. The stoppers' tight seal prevents the ingress of external moisture or gases, thus extending the shelf life of the lyophilized product and ensuring its therapeutic effectiveness.

Compatibility with Automated Manufacturing

Modern pharmaceutical manufacturing relies heavily on automated systems for vial filling, stopper insertion, and sealing. Freeze-dried butyl rubber stoppers are designed to be compatible with these high-speed processes.

Their dimensional consistency and surface characteristics support smooth handling, reducing downtime and minimizing defects during manufacturing. This compatibility increases production efficiency and reduces costs, which is beneficial for large-scale pharmaceutical operations.

Regulatory Compliance and Quality Assurance

Medical freeze-dried butyl rubber stoppers are manufactured under stringent quality control protocols in compliance with regulatory standards set by agencies such as the FDA and EMA. They are subject to thorough testing, including extractables and leachables analysis, to ensure no harmful substances migrate into the drug product.

Their use in parenteral drug packaging is supported by extensive documentation and certifications, providing pharmaceutical companies with the assurance needed to meet regulatory submission requirements.

https://www.klstopper.com/product/pharmaceutical-rubber-stopper/lyophilization-freezedried-butyl-rubber-stoppers.html

Excellent sealing performance

Replacement of barrier rubber stoppers

Provides special chlorobutyl rubber formula for good compatibility

With pharmaceuticals Special treatment process and the most stringent process control ensure the cleanliness of the rubber stopper

Microbiological testing is to ensure the safety of rubber stoppers

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness