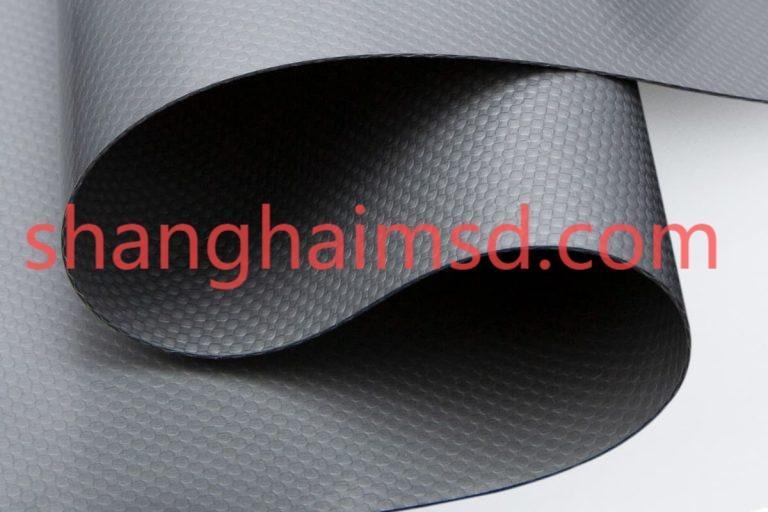

TPU Compound Fabric for Tents and Trekking Equipment

The demand for outdoor gear that is both resilient and adaptive has led to the development of innovative materials like TPU Compound Fabric , which blends durability with flexibility for optimal performance. Shanghai MSD International Trading Co., Ltd. supplies this advanced textile solution, which is widely used in tents, backpacks, and waterproof apparel that must perform under challenging environmental conditions.

TPU Compound Fabric is created by bonding thermoplastic polyurethane (TPU) with a textile base—usually nylon or polyester—through processes like lamination or coating. This fusion results in a fabric that combines the structural integrity of woven textiles with the elastic, waterproof, and abrasion-resistant qualities of TPU. For outdoor applications, this means enhanced resistance to tears, punctures, and environmental wear, without compromising on weight or comfort.

In the world of technical tents and shelters, the material’s water resistance and windproof nature make it a top-tier option. TPU-coated fabrics repel water under high pressure, allowing them to withstand storms and long-term exposure to rain. Unlike traditional PU coatings, TPU does not degrade easily under UV rays, ensuring longer product life in sun-exposed environments. Campers and expedition teams rely on these fabrics for protection when in remote or harsh terrains.

Backpacks and dry bags made with TPU compound layers benefit from both flexibility and structural strength. The fabric is pliable enough to allow complex shaping and seams, yet strong enough to carry heavy loads or protect electronics and gear from water ingress. It also resists oil, mud, and chemicals, making it ideal for multi-environment use—from river rafting to desert hiking.

Another key advantage lies in the fabric’s temperature stability. TPU maintains flexibility in cold conditions where other materials can crack or stiffen. This makes it an excellent candidate for winter sports gear, such as ski boot covers, alpine packs, or snowmobile accessories. At the same time, it remains breathable, allowing moisture from sweat or condensation to escape—critical for user comfort.

The fabric is also known for its weldability. Unlike many other synthetic materials that require stitching, TPU surfaces can be heat-sealed or RF welded to create seamless, waterproof joints. This reduces the need for adhesives and sewing, simplifying manufacturing while enhancing performance. Many brands now opt for this clean-construction technique in waterproof garments, inflatable structures, or even mobile shelters.

From a design standpoint, TPU Compound Fabric offers smooth surfaces that can be printed or color-treated for branding or functional marking. Whether used in safety equipment with high-visibility tones or in minimalistic outdoor fashion, the material adapts to both utility and aesthetic requirements.

Shanghai MSD International Trading Co., Ltd. offers a broad selection of TPU fabrics with variations in thickness, texture, and base fabric type. Their technical support helps clients select the right material for specific applications, including custom lamination requirements or certifications for flame retardancy and environmental compliance.

As consumers become more conscious of product longevity and material origin, TPU fabric stands out for being free of plasticizers and recyclable under the right systems. Certain grades meet eco-certification standards, supporting brands that prioritize sustainability alongside performance.To explore Shanghai MSD’s complete selection of TPU Compound Fabric and discover solutions tailored for your outdoor product line, please visit: https://www.shanghaimsd.com/product/ .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness