Tailored Shaft Technology for Global Demands

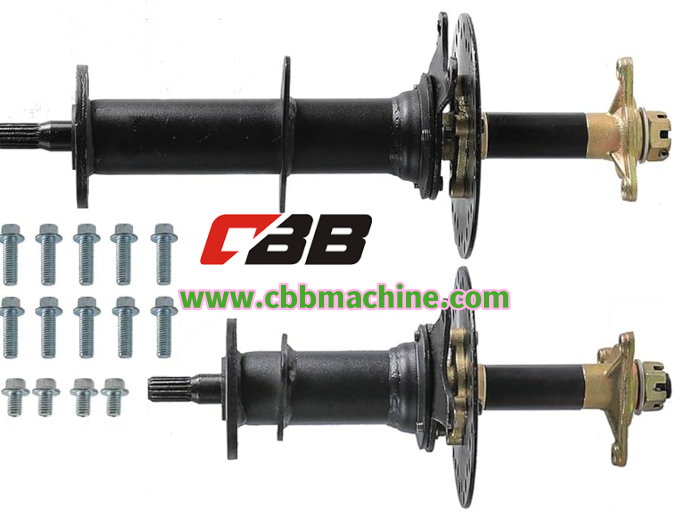

In the ever-evolving industrial sector, CBBMachine has established itself as a pioneer among Differential Shaft manufacturers , delivering components that redefine reliability and efficiency in power transmission. Designed to meet the rigorous demands of industries like automotive, aerospace, and renewable energy, CBBMachine’s differential shafts ensure seamless torque distribution and operational stability. By merging cutting-edge engineering with user-centric design, the company empowers businesses to overcome complex mechanical challenges.

Addressing Critical Industrial Needs Modern machinery requires components that adapt to high-speed operations, variable loads, and harsh environments. Traditional shafts often fail to maintain alignment under stress, leading to costly downtime. CBBMachine’s differential shafts tackle these issues through precision-balanced construction and heat-resistant alloys. Their ability to minimize vibration and wear ensures longevity, even in applications such as wind turbines, robotic arms, and heavy-duty conveyor systems.

Engineering Excellence in Every Detail CBBMachine’s commitment to quality shines in its meticulous manufacturing processes. Each differential shaft undergoes rigorous testing to guarantee micron-level accuracy and optimal load distribution. Advanced coatings prevent corrosion, while modular designs allow easy integration into existing setups. These features not only reduce maintenance costs but also enhance energy efficiency, aligning with global sustainability goals.

Versatility Across Industries From automotive assembly lines in Germany to mining operations in Chile, CBBMachine’s solutions cater to diverse applications. The differential shaft’s adaptability extends to hybrid vehicles, where precise power splitting is critical, and to packaging machinery requiring consistent speed control. This versatility positions CBBMachine as a strategic partner for businesses aiming to scale operations without compromising performance.

Sustainability at the Core As industries prioritize eco-friendly practices, CBBMachine integrates sustainability into its production ethos. The differential shafts’ lightweight design reduces material waste, and energy-efficient manufacturing processes lower carbon footprints. By extending equipment lifespan and minimizing resource consumption, CBBMachine supports clients in achieving both operational and environmental objectives.

Unlock Superior Performance Ready to upgrade your machinery with precision-engineered solutions? Visit www.cbbmachine.com to explore how CBBMachine’s differential shafts can revolutionize your operations. Discover innovation built for durability and efficiency—your next leap in productivity starts here!

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness